FSJZ43 impacting flour loosener / FSJQ51 Punchy impacting flour loosener Working principle The impacting flour loosener utilizes the impellor, dowel pin and impact ring rotating at high speed to turn the material and endow the material with huge centrifugal force. The material is being impacted incessantly between the impellor, dower pin and the impact ring, so that flakes formed in the milling process are loosened, wheat kernels are crushed, and the endosperm adsorbed on the bran is separated.

CharacteristicsThe shell is welded steel structure, and the machine parts are durable, and the maintenance cost is low. The low carbon alloy steel dowel pin has its surface nitrided and carburized so that good wear-resisting property is ensured.

Advanced fabrication means and rational manufacturing process guarantee the fabrication accuracy and quality of the equipment.

The rotor receives high-accuracy dynamic balance check-out, with smooth and reliable operation.

The reasonable design makes higher loosening efficiency.

Application The machine is mainly used to aid the flour milling machine and flat screen by impacting the intermediate products in the flour making process. It results in higher flour-sifting efficiency. It is used to impact the flakes from the front and middle section mills with the smooth roller or to be used to kill vermin by impacting. Its reasonable use in the flour making process can effectively improve both the production yield and quality.

Main specifications and technical parameters

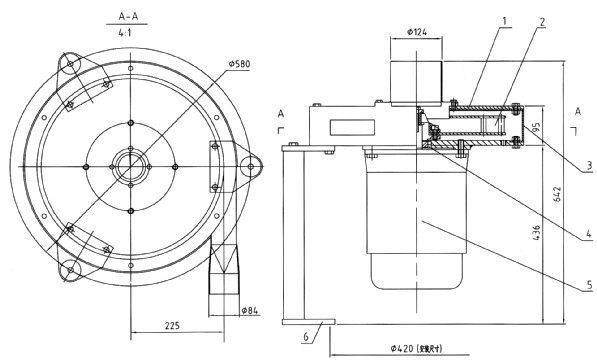

FSJZ43Punchy impacting flour loosener Installing the Chart

1. shell 2.plate rejection 3.Case 4.seal 5. the electrical 6.the mounting foot

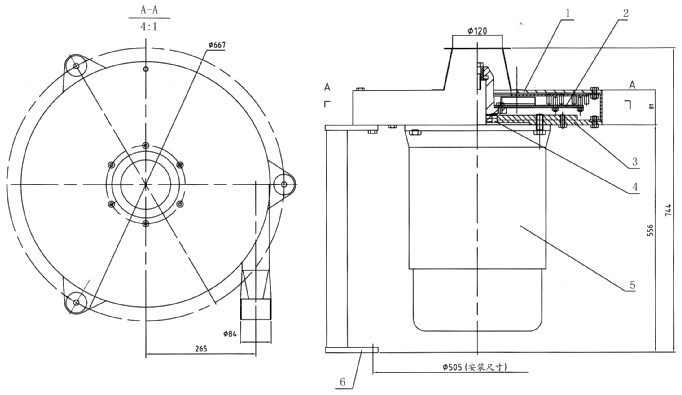

FSJQ51Strong loose powder install chart

1. shell 2.plate rejection 3.Case 4.seal 5. the electrical 6.the mounting foo

|